The expediency of applying electromagnetic filters (EMF) in the power industry is justified by the fact that in the coolant there are corrosion products, mainly represented by magnetite (Fe3O4) and maghemite ( Fe2O3), which have ferromagnetic properties. The operating principle of the EMF is based on selective capture of ferromagnetic particles of ferriferous impurities (60...80 % from the general content of iron) by high-gradient magnetic field while media is moving along its technological path.

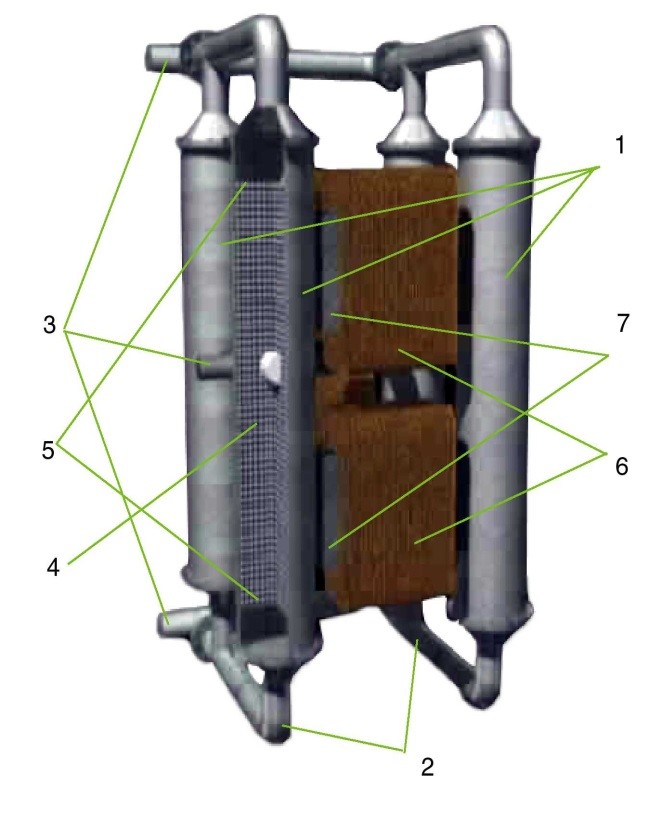

The initial filtering material is light packing covered with a layer of ferromagnetic material and which is the main filter substance.

The efficiency of the EMF to clean the environment from ferriferous impurities depends on:

- technical parameters (strength of the external magnetizing field; length of the filtering layer of the packing; filtration rate; diameter of granules of the packing);

- properties of impurities, from which the medium is cleaned (average particle size; magnetic properties of the particles);

- magnetic impurities share of total ferruginous impurities;

- dynamic viscosity of the filtered medium.

The liquid being cleaned passes through the filtering packing, where, under the influence of magnet field, it is cleaned from ferromagnetic impurities that are deposited on the surface of the packing. The flow of liquid passing through the packing does not experience any significant hydraulic resistance as a density of granules in the packing is of 40...60 %. Periodically, usually within 6...10 hours, the regenerative cycle is activated that lasts 10...15 minutes and, as its result, the packing is cleaned from the impurities deposited on it. During filter regeneration, the flow of liquid to be purified temporarily bypasses it through a by-pass. The coils of the electromagnets are de-energized and the packing become demagnetized, thereby the particles precipitated on the packing cease to be kept by it and are washed off by reverse flow of cleaned liquid into the holding tank. To intensify the regeneration process the air bubbling can be applied.

During operation the packing and magnetic cores form a closed magnetic circuit with intensity of magnetic field up to 70...100 kA/m. In the capacity of filling agent of the filtering packing a specially manufactured material with coefficient of packing 0.4...0.6 is used, which have high magnetic properties at density of 1.2...2.0 g/cm3.

The SE «Czechpol Energy» offers effective and high-performance designs of ELECTROMAGNETIC FILTERS, which allow:

- High-efficiency removal of magneto-susceptible impurities from liquid and gaseous media attaining temperature up to 500 °C;

- Cleaning of the highly corrosive chemical media: sulfuric, nitric and hydrochloric acid, ammonia, ammonia water and other;

- Removal of particles smaller than 0.1 µm from different media;

- To combine compactness of the plant with its high efficiency;

- Reduce to a minimum the operational control and maintenance, and if necessary, to fully automate the operation process.